2024 Soybean Microbial Product Trials

go.ncsu.edu/readext?1064488

en Español / em Português

El inglés es el idioma de control de esta página. En la medida en que haya algún conflicto entre la traducción al inglés y la traducción, el inglés prevalece.

Al hacer clic en el enlace de traducción se activa un servicio de traducción gratuito para convertir la página al español. Al igual que con cualquier traducción por Internet, la conversión no es sensible al contexto y puede que no traduzca el texto en su significado original. NC State Extension no garantiza la exactitud del texto traducido. Por favor, tenga en cuenta que algunas aplicaciones y/o servicios pueden no funcionar como se espera cuando se traducen.

Português

Inglês é o idioma de controle desta página. Na medida que haja algum conflito entre o texto original em Inglês e a tradução, o Inglês prevalece.

Ao clicar no link de tradução, um serviço gratuito de tradução será ativado para converter a página para o Português. Como em qualquer tradução pela internet, a conversão não é sensivel ao contexto e pode não ocorrer a tradução para o significado orginal. O serviço de Extensão da Carolina do Norte (NC State Extension) não garante a exatidão do texto traduzido. Por favor, observe que algumas funções ou serviços podem não funcionar como esperado após a tradução.

English

English is the controlling language of this page. To the extent there is any conflict between the English text and the translation, English controls.

Clicking on the translation link activates a free translation service to convert the page to Spanish. As with any Internet translation, the conversion is not context-sensitive and may not translate the text to its original meaning. NC State Extension does not guarantee the accuracy of the translated text. Please note that some applications and/or services may not function as expected when translated.

Collapse ▲The NC State Soil Microbiome Extension program conducted small plot field trials in 2024 evaluating microbial biostimulant seed treatments. Microbial biostimulants are beneficial organisms (bacteria and fungi) that may support plant health and increase crop yield by increasing plant nutrient access/efficiency or enhancing plant stress tolerance. The objective of this study was to evaluate field efficacy of microbial seed treatments on soybean production across North Carolina’s regional environments.

Study Design

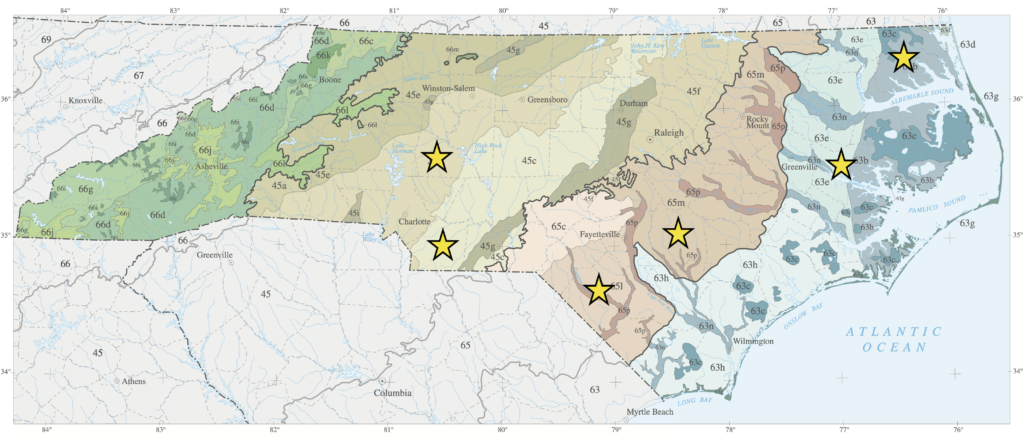

Trials were installed at 6 OVT county locations spanning three ecoregions (Figure 1) including Beaufort and Pasquotank (Tidewater), Robeson and Sampson (Coastal Plain), and Rowan and Union (Piedmont). See Supporting Information for soil characteristics, site details, and 2024 weather data.

Figure 1. U.S. Geological Survey and Environmental Protection Agency (EPA) map of North Carolina ecoregions. Stars indicate location of OVT small plot trial location.

Four microbial seed treatments (Table 1) plus a non-treated control were installed at each location in a randomized block design (4 x 20 ft rows with 15” row spaces) with 16 replicates per treatment. We used Asgrow Bayer Crop Sciences AG54XF0 (MG 5.4) which are XF/SR (trait) and pre-treated with Acceleron Fungicide and Insecticide. Product application rates followed manufacturer’s instructions, with a total application volume of 5 fluid oz/100 lbs of seed for liquid formulations (volume adjusted with DI water). Seeds were planted within 5-7 days of treatment.

| Product | Company | Guaranteed Analysis | Formulation | Application Rate |

| BioCoat Gold | Advancing Eco Agriculture | Soluble potash 2%; calcium 5%; 4.0% humic acids; 0.006%; cfu/g each of: Arthrobacter globiformis (1.25x104); Azospirillum brasilense (1.25x105); A. lipoferum (1.25x104); Azotobacter chroococum (1.25x104); A. paspali (1.25x103); A. vinelandii (1.25x104); Bacillus amyloliquefaciens (1.25x105); B. atrophaeus (1.25x104); B. licheniformis (1.25x104); B. megaterium (1.25x104); B. pumilus (1.25x105); B. subtilis (1.25x104); B. thuringiensis (1.25x104); Brevibacillus brevis (1.25x105); Lysinibacillus sphaericus (1.25x105); Brevibacillus brevis (1.25x105); Lysinibacillus sphaericus (1.25x105); Micrococcus luteus (1.25x104); Pseudomonas fluorescens (1.25x104); P. putida (1.25x105); Rhodouseudomonas palustris (1.25x103); Rhodospirillum rubrum (1.25x103); Streptomyces griseus (1.25x104); propagules/g each of: Glomus intraradices (32.5); G. deserticola (3); G. etunicatum (3); G. clarum (3); G. claroideum (3); G. mosseae (3); Gigaspora albida (3) | Powder seed treatment | 4 mass oz. per 100 lbs seed |

| Biotrinsic M34 FP | Indigo Ag | Brevibacillus subtilis (1.0×107 cfu/g) | Powder seed treatment | 0.57 mass oz. per 100 lbs seed |

| Bio800 | Holganix | Water 88.8%; molasses 10.8%; amino acids 0.1%; humic acid 0.16%; kelp 0.06%; fulvic acid 0.04%; cfu/g each of Levilactobacillus acidifarinae (1.4×105 ); Le. brevis (3.9×106); Lacticaseibacillus manihotivorans (2.7×105); L. rhamnosus (1.8×105); Lentilactobacillus parakefiri (1.5×106); Lactiplantibacillus penosus (1.1×107 ); La. plantarum (9.3x106); Trichoderma harzianum (2.5x105 ); Glomus aggregatum (8.0×103); G. entunicatum (8.0×103); G. intraradices (8.0×103); G. mosseae (8.0×103) | Liquid in-furrow treatment *** (tested as a seed treatment) | 5 fl. oz per 100 lbs seed |

| EndoShield ST | JABB of the Carolinas | 1% Beauveria bassiana (1×108 cfu/ml), 99% soybean oil adjuvant | Liquid seed treatment | 1 fl. oz per 100 lbs seed |

Results

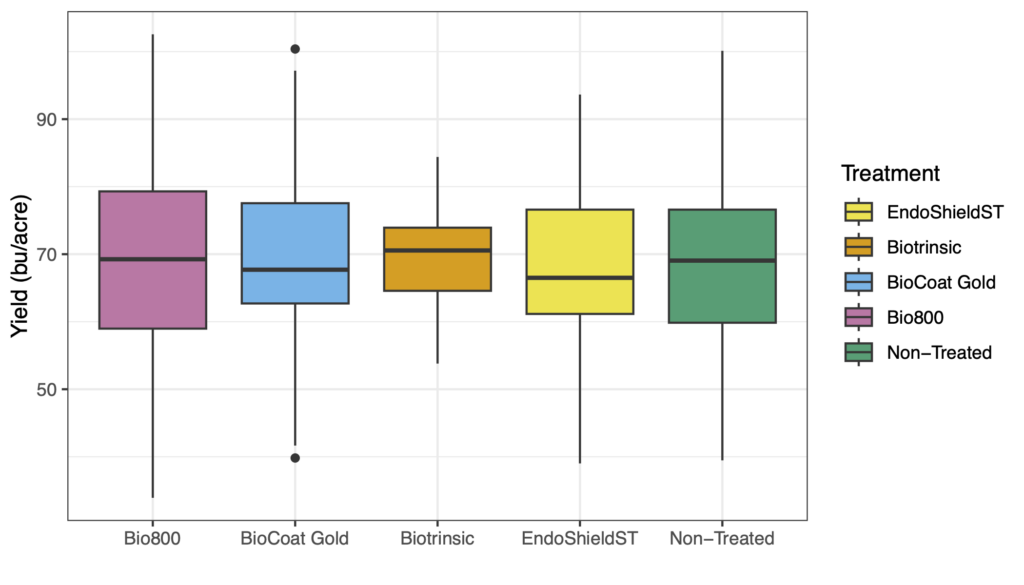

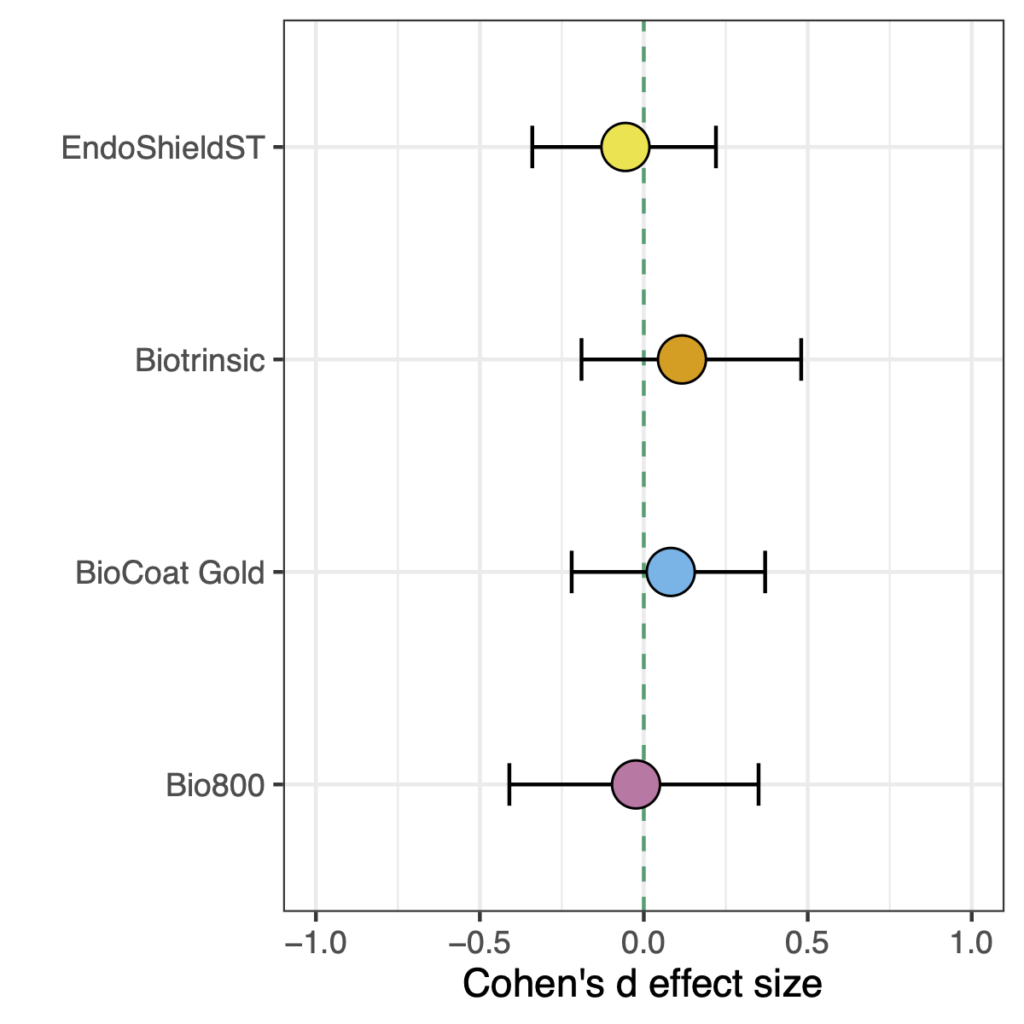

Across all locations, soybean yield did not differ between seed treatments or non-treated controls (Figure 2), and there is negligible difference in yield outcomes between treated and non-treated plots (Figure 3).

Figure 2. Box plots show distribution and median (black line) yield measurements (bu/acre) for microbial treatments and non-treated controls across all locations.

Figure 3. Circles show the effect size, or the magnitude of differences in yield between treated and non-treated controls across the entire study. Positive values indicate yield is greater than control, and negative values indicate yield is less than control. Effect size of less than 0.2 is considered negligible, and effect size of 0.5 is small.

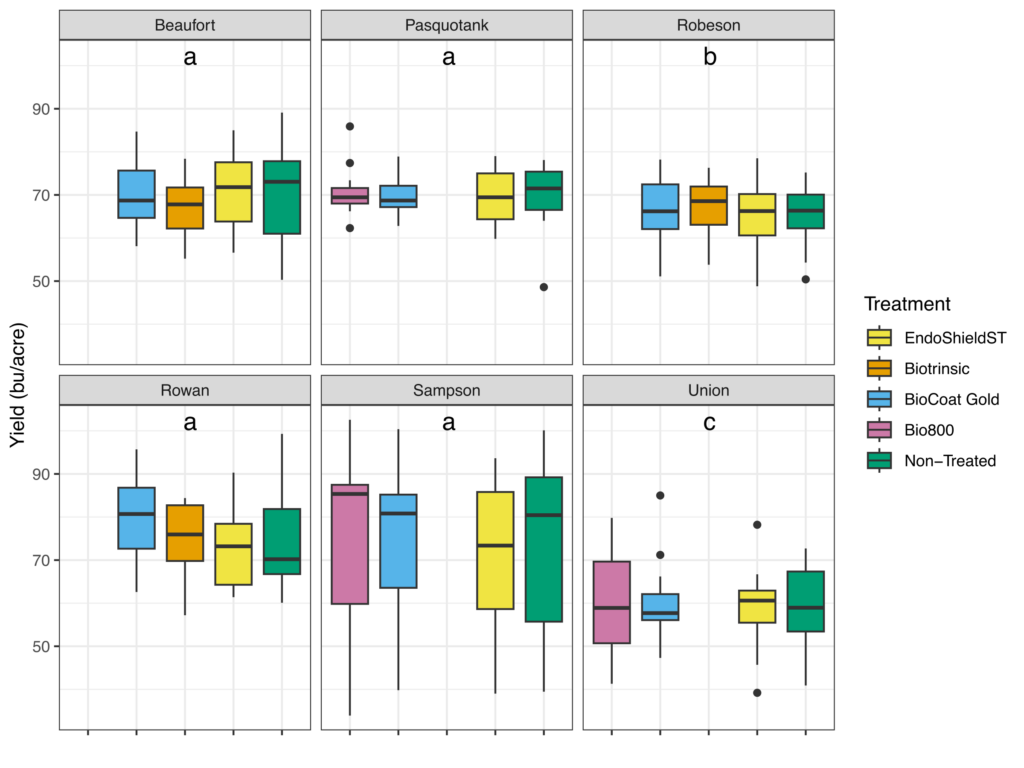

Yield varied significantly between locations (P-value < 0.05), and relative yield differences are consistent with 2024 OVT results (Table 2). Within locations, there are no yield differences between microbial seed treatments or non-treated controls (Figure 4).

Figure 4. Box plots show distribution and median (black line) yield measurements (bu/acre) for microbial treatments and non-treated controls at each location. Letters indicate significant yield differences (P-value < 0.05) between locations (see Table 2).

| Location | Average Yield (bu/acre) |

| Beaufort | 69.7 (a) |

| Pasquotank | 69.9 (a) |

| Robeson | 66.3 (b) |

| Rowan | 75.2 (a) |

| Sampson | 73.4 (a) |

| Union | 59.5 (c) |

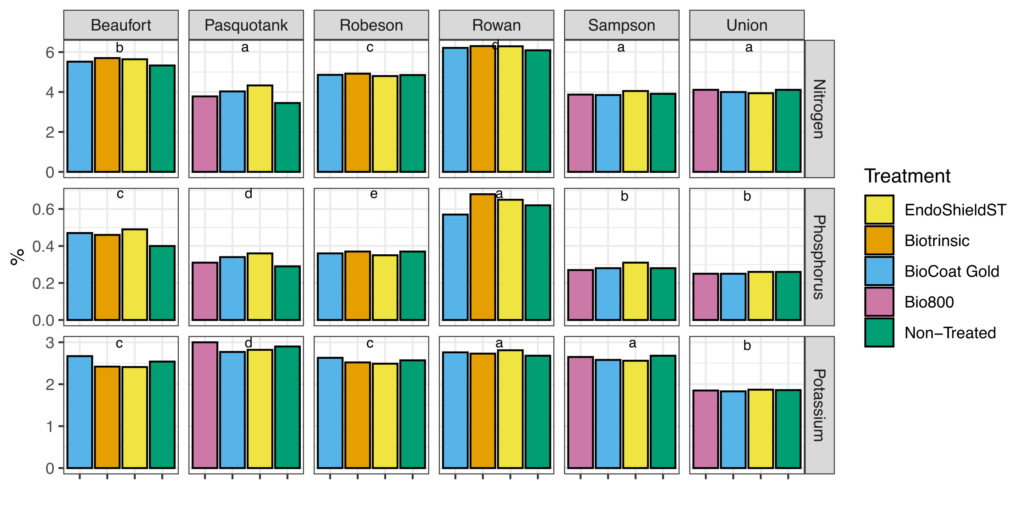

Finally, since biostimulants may increase plant nutrient uptake, we measured leaf nutrient content at mid-late vegetative stage (V4-V6). Macronutrients varied significantly between locations (P-value < 0.05) but not between microbial treatments (Figure 5). Note that all plant nutrient levels were in the normal, healthy range.

Figure 5. Bar plots show the leaf nutrient content (%) for each microbial treatment and non-treated control across locations (columns) for macronutrients nitrogen, phosphorus, and potassium (rows). Letters indicate significance groups or locations with significantly different nutrient measurements (P-value < 0.05).

Summary

- Soybean yield varies between locations, and yield patterns are consistent with NC State 2024 Soybean OVT site comparisons.

- Microbial biostimulant seed treatments had no significant impact on yield. Yield differences between treated and non-treated controls were negligible.

- Environmental variables between production environments drives differences in field performance and soybean yield. These variables may include agronomic history and practices, weather, soil biogeochemistry, and differences in soil microbiome diversity.

Supplementary Information

Acknowledgements

Dr. Mallory Choudoir (Assistant Professor and Extension Specialist in the Department of Plant and Microbiology) conducted the study and analyzed all results with the help of lab members including Madaris Serrano Perez, Izzy Alexander, Akieliah Robinson, and Bella Borrero. The NC State Official Variety Testing (OVT) program and Ryan Heiniger planted and harvested the trial. This work was funded by the North Carolina Soybean Producers Association.